News List

Are you tired of sacrificing speed for precision when printing custom paper bags? Do frequent last-minute theme orders for hotels and bars leave you scrambling to meet deadlines? Switching between bag materials often causes costly downtime, too. For specialty printing businesses, these pain points aren’t just inconveniences—they’re barriers to winning more clients and scaling operations. In Episode 5 of Single Pass Unleashed: 1000 Specialty Material Printing Solutions, we highlight how the Single Pass paper bag printer eliminates these trade-offs. It delivers consistent, high-quality prints across every paper bag type in a single, lightning-fast pass.

For packaging manufacturers and brand owners, paper bag printing comes with unique, bag-specific challenges. These issues slow operations and compromise results.

Worse yet, switching between these diverse bag types means lengthy setup adjustments. It also leads to costly downtime and wasted materials. For businesses catering to retail, food, and hospitality clients, these inefficiencies are a major growth bottleneck.

The Single Pass paper bag printer is engineered to master the unique demands of all paper bag materials. It proves why Single Pass technology is the gold standard for specialty printing. Here are three core advantages that set it apart:

Unlike multi-pass printers that require repeated runs to build ink coverage, Single Pass technology prints full designs in one continuous pass. This means a 50,000-unit run of shopping bags takes just 2 days instead of 7. Even small-batch custom orders—like 500 limited-edition coffee bags—are ready in minutes. This lets you capitalize on short-turnaround opportunities without sacrificing quality.

The Single Pass paper bag printer adapts seamlessly to every paper bag application. No manual tweaks are required:

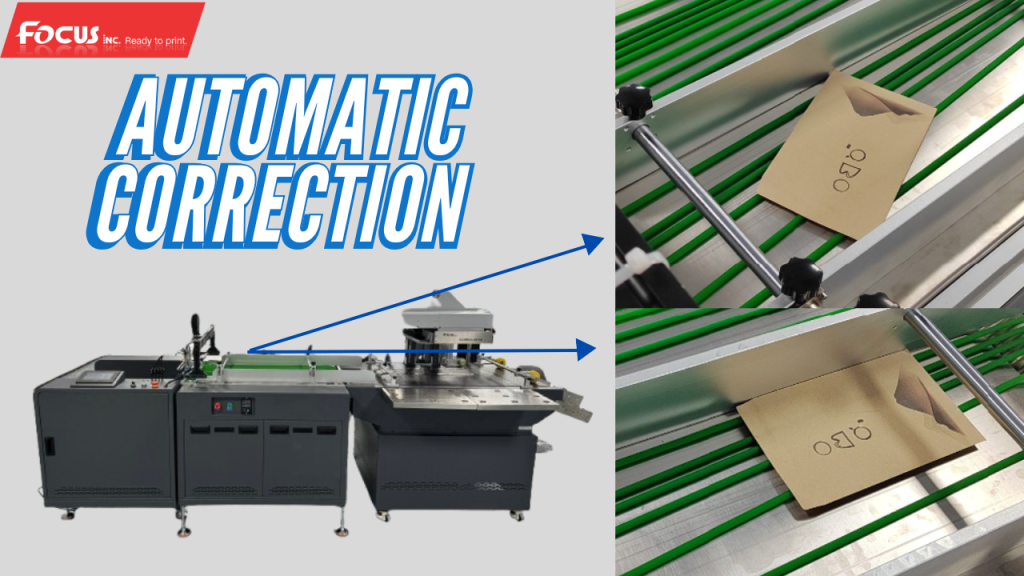

Single Pass printing eliminates the misalignment and ink inconsistency that plagues multi-pass machines. Every bag—whether bulk retail runs or small artisanal batches—boasts crisp text and vivid colors. These details make brands stand out on shelves or in hospitality venues. For specialty printing businesses, this consistency turns first-time clients into repeat partners.

What truly sets our Single Pass paper bag printer apart from rivals is its precision-engineered flexibility and user-centric design. First, it has integrated variable data printing (VDP) capabilities. Unlike competitors’ systems that need aftermarket modules, our printer natively supports dynamic data encoding. It enables seamless printing of unique barcodes or personalized messages on every unit, with zero impact on throughput.

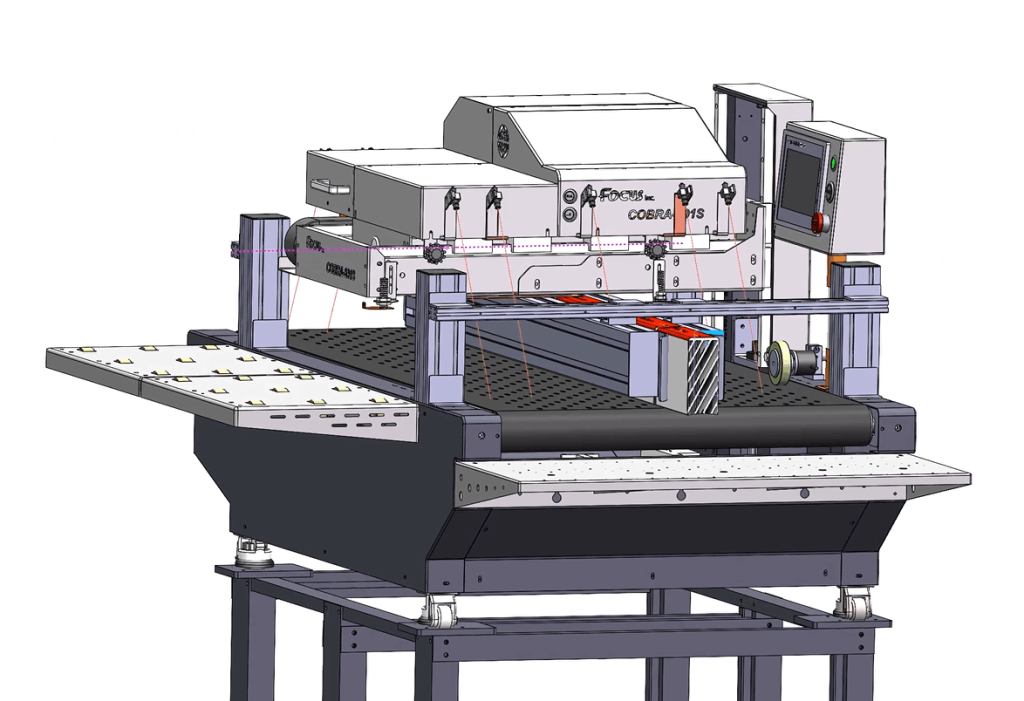

Additionally, it optionally features a dual-feeder system. A precision friction feeder handles standard 200–400 gsm paper bags at high speed. Meanwhile, a vacuum-assisted feeder gently transports delicate 60–80 gsm bread bag paper or rigid 500+ gsm retail cardstock. This minimizes material skew and jamming rates to <0.01% for mixed-material orders.

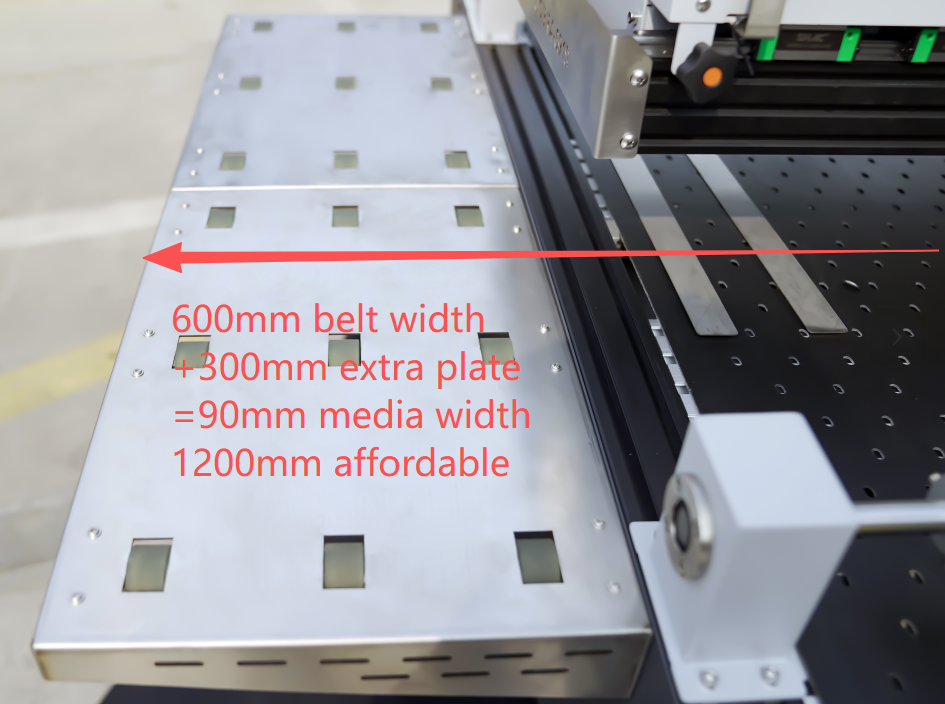

A key edge is the 1.2-meter wide input plate—30% wider than comparable models in the same footprint. It accommodates oversized bags without manual reorientation, boosting line efficiency.

Beyond paper bags, the printer’s modular design delivers unmatched cross-material versatility. With bolt-on custom jigs, it adapts to print on corrugated boxes or book edges for personalized publishing. It achieves a maximum printing thickness of 25 centimeters, supporting bulky substrates outside most single-pass printers’ range.

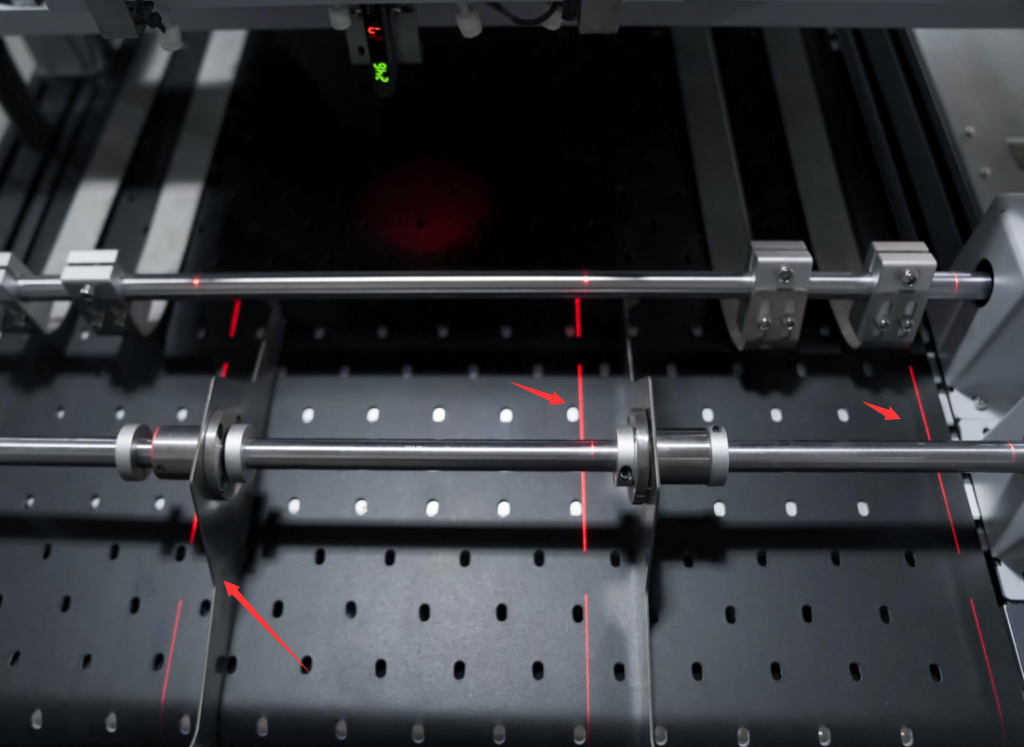

Moreover, calibration is streamlined via a built-in red laser alignment line. The collimated laser projects a high-contrast reference mark for the zero printing start position. Operators can fine-tune positioning with ±0.1 mm accuracy without trial prints. This cuts job changeover time by 30% compared to manual calibration machines.

More advantages please get in touch with our techniques to receive it.

To showcase the Single Pass paper bag printer’s impact, here are four client wins across retail, food, and hospitality sectors:

A leading fashion brand needed 50,000 custom metallic-logo shopping bags for its summer sale in different designs. Using our Single Pass printer, the manufacturer completed the order in 72 hours—3 days ahead of schedule. The bags’ scratch-resistant prints held up through heavy retail use. The brand reported a 25% increase in social media shares from customers showing off their purchases.

A specialty coffee roaster launched limited-edition bags with hand-drawn farm illustrations. The Single Pass printer delivered smudge-proof, food-safe prints on matte, airtight bags. It produced a 10,000-unit run with zero defects. The roaster saw a 30% sales lift for the line, with customers praising the packaging’s premium look.

A local bakery needed 1,000 custom bags with its logo and “fresh baked daily” messaging. The Single Pass printer handled thin, grease-resistant paper without jams. It produced the full batch in under an hour. The bakery rolled out the packaging the same day, and customer recognition increased by 40% in the first month.

A printing business serves 50% of the hotels, restaurants, and bars in its country. It needed a solution for frequent custom theme orders. For a luxury hotel’s tropical wedding fair, it produced 3,000 palm-patterned welcome bags in 3 hours—with no setup delays from prior restaurant takeout bag runs. For a bar’s Halloween pop-up, it printed 1,500 spooky cocktail to-go bags in under an hour. The client reported a 40% reduction in turnaround time and a 25% increase in repeat hospitality business.

In Single Pass Unleashed Ep 5, we’ve seen that the Single Pass paper bag printer isn’t just another piece of equipment. It’s a tool to expand your specialty printing capabilities. By mastering retail, food, gift, and hospitality paper bags, you can:

As we continue our journey through 100 specialty material solutions, it’s clear that Single Pass technology turns “impossible” printing challenges into competitive advantages.

If you’re tired of choosing between speed and quality for paper bag projects, it’s time to upgrade to a Single Pass paper bag printer. Contact our team today to request a free demo. Discover how Episode 5’s star technology can revolutionize your specialty printing business.

Submit Request