News List

For decades, flexography and offset lithography ruled the printing world. But in 2025, brands face a new reality: consumers demand hyper-personalized packaging,variable data and QR Codes printing , faster product launches, and eco-friendly practices. Traditional methods can’t keep up. This article is a single pass inkjet printer buyer’s guide

Enter single pass inkjet printing—the technology reshaping industries from labels to textiles. If you’re asking:

You’re in the right place.

In this guide, Focus Inc. (pioneers in industrial inkjet solutions) breaks down why single-pass dominates modern printing—and how to choose your perfect system.

Let’s get straight to the data-driven comparison:

| Flexo/Offset Lithography | Single Pass Digital Inkjet |

|---|---|

| ✅ Best For: Ultra-high-volume static jobs (500k+ units). | ✅ Best For: Short runs, variable data, fast turnarounds. |

| ⏱️ Setup Time: 2–4 hours (plate mounting, ink mixing). | ⏱️ Setup Time: 0 minutes (no plates or wash-ups). |

| 💰 Cost per Job: High for short runs (plates, wasted ink/substrates). | 💰 Cost per Job: 60–80% lower for batches under 10k. |

| 🌱 Sustainability: 30–40% material waste during setup. | 🌱 Sustainability: Near-zero setup waste, energy-efficient. |

Real-World Impact:

A craft brewery saved $18,000/year by switching to single pass digital inkjet printer for seasonal beer labels. No plates = no sunk costs for short runs.

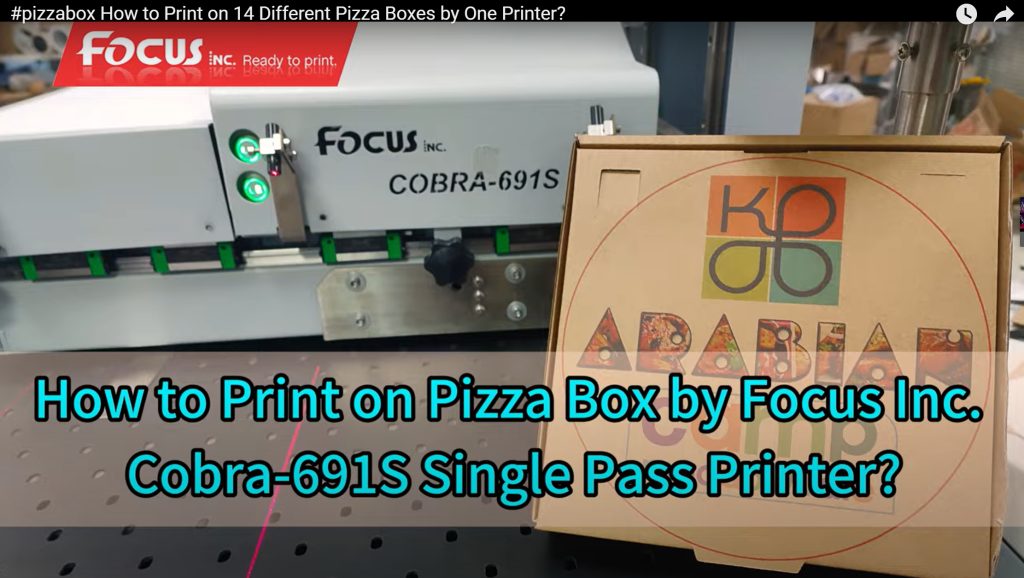

14 different pattern samples are printed continuously

Ask these before buying:

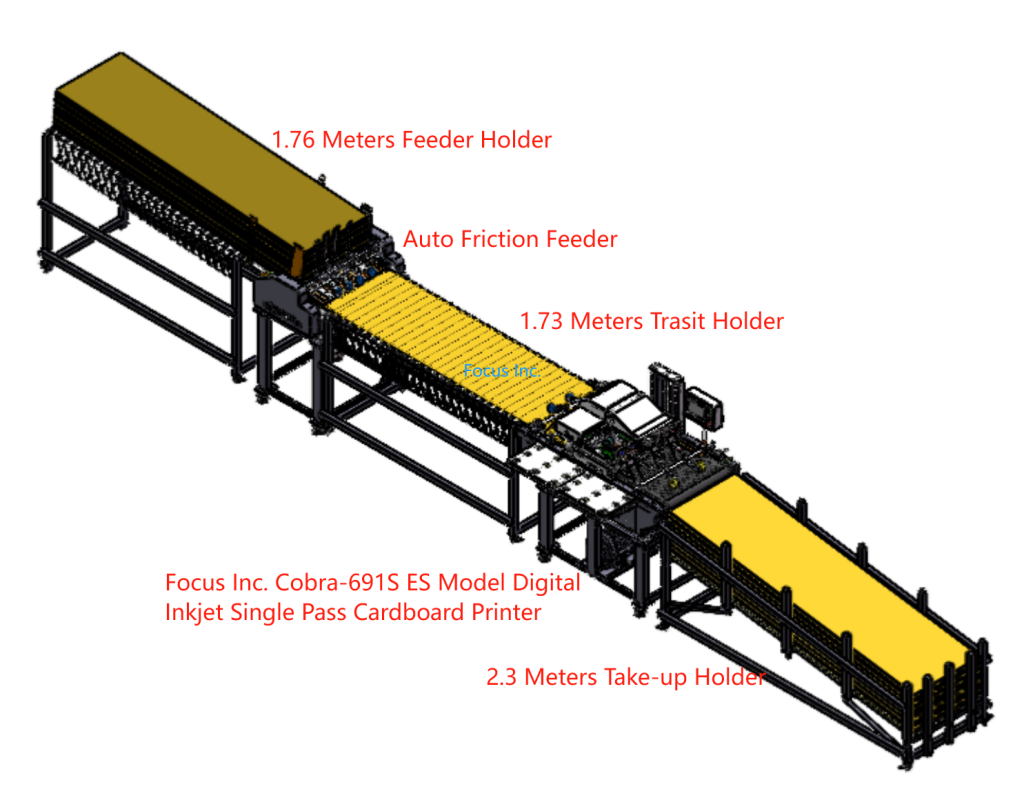

Challenge: A large size product brand needed 8,000 unique holiday gift boxes (size 2 meters unfolded) —each with personalized QR codes—in 3 days.

Solution:

Q: Is single-pass inkjet reliable for long runs?

A: Absolutely. Newer models rival offset speeds (500m+/min) for high-volume work.

Q: What about color accuracy?

A: Advanced spectrophotometers ensure Pantone-matching within ΔE<2.

Q: Can I print white ink?

A: Yes—top-tier systems offer opaque white layers for dark substrates with UV curing Single pass digital printing system.

Q: "What’s the best usage of single-pass inkjet printer?"

A: "Single pass inkjet printer can apply with UV-curable inkjet printing, textile printing solutions, fast-turnaround e-commerce printing, high-durability packaging, direct to food printing and other sustainable manufacturing technology as customers' demands ."

Q: "Can single-pass inkjet handle high-volume e-commerce orders?"

A: "Yes! High-speed single-pass printers like FocusInc. Viper-391S and CR391 model system deliver 50+ label pieces per minute, perfect for fast-turnaround e-commerce packaging."

From short-run packaging to custom textile printing, single-pass inkjet is revolutionizing industries with low-cost, high-speed solutions, variable data printing for personalized labels and packaging—proving it’s not just a trend, but the future of sustainable manufacturing..

Ready to explore?

📥 Download Focus Inc.’s More Customers' Examples to see how much you’ll save.

📞 Book a free consultation with our engineers to match your needs to the perfect machine.

Submit Request