News List

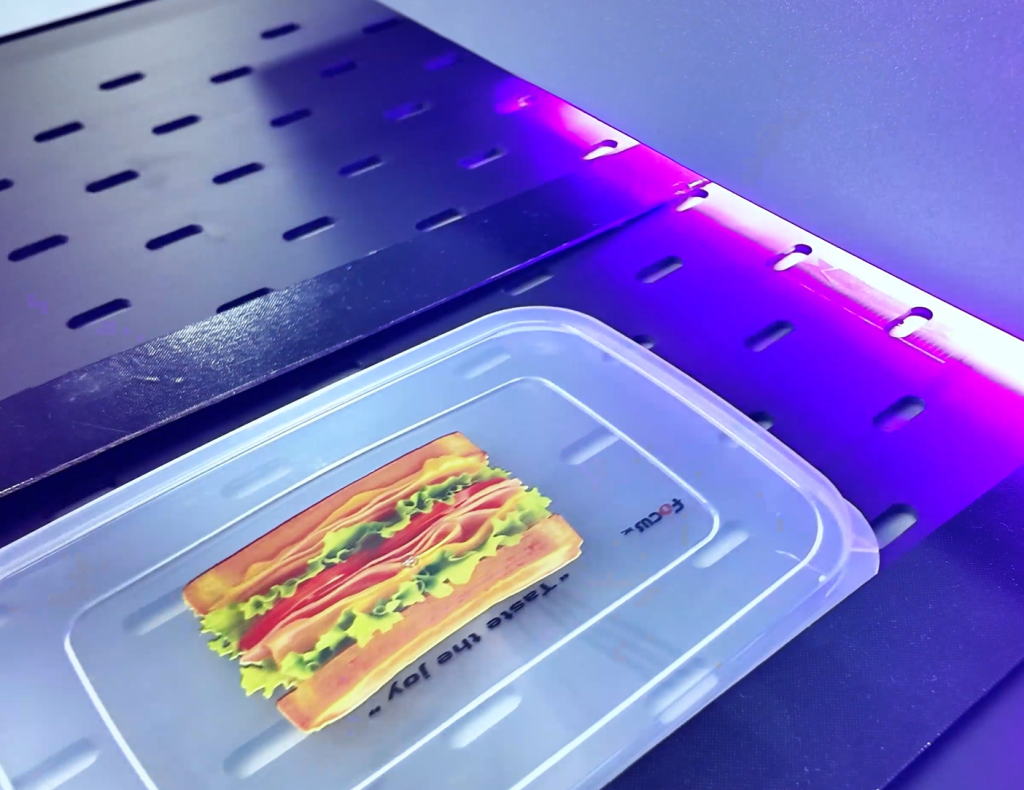

Food delivery packaging and takeaway packaging is more than a simple container. It’s your clients’ brand calling card, a protector of food quality, and a non-negotiable safety barrier with their branding. Our 1000 printing solutions challenge zeroes in on this high-stakes sector. Moreover, the UV single pass digital inkjet printing machine stands out as the core tool. It overcomes traditional printing limitations, helping you win more packaging business.

Traditional food delivery packaging printing often holds businesses back. For example, flexo printing locks you into high plate costs. It also leaves no room for small-batch custom orders. These orders are critical when serving boutique cafes or chain restaurants. Meanwhile, heat transfer produces patterns that peel off easily. This damages your reputation with clients. Fortunately, the UV single pass printer solves these pain points seamlessly. It uses one-pass full-color printing and instant curing for flawless, reliable results.

The global food delivery packaging market is booming. It’s projected to hit $89.6 billion by 2030, with a 7.2% CAGR. This is your chance to expand revenue. Additionally, food brands demand more now. They range from local eateries to national chains. Their needs include customized designs, fast turnaround, and strict food safety compliance. The UV single pass printer isn’t just equipment. It’s your key to tapping this lucrative market by meeting all these core demands.

It works seamlessly with all mainstream food delivery packaging materials. These are the ones you handle daily, such as kraft paper burger boxes and PP/PE salad bowls. It also suits aluminum foil snack bags and compostable PLA clamshells. Therefore, you don’t need to invest in multiple machines for different substrates. One UV single pass printer covers your entire workflow.

Built-in special pre-treatment modules ensure firm ink adhesion. This is true even on smooth PP surfaces or porous kraft paper. As a result, there’s no more ink bleeding, peeling, or rework. This helps you deliver consistent quality to your clients every time.

We use food-grade UV curable inks. They comply with strict global standards. The inks are non-toxic, odorless, and free of harmful solvents. Thus, you can safely serve food brands. This eliminates compliance risks that could derail client relationships.

Cured inks resist oil, water, friction, and low temperatures. The temperature range is from -20℃ to 60℃. This keeps patterns intact during delivery and refrigeration.

It’s equipped with high-performance UV-LED curing systems. These cure ink in just 0.2 seconds. There’s no smudging and no waiting. For roll materials like packaging films, printing speed hits 180 m/min. This lets you fulfill large orders faster than competitors. You can also capitalize on peak delivery seasons.

Additionally, it supports 24/7 continuous production. This meets peak demand from food delivery platforms. The demand surges during holidays and rush hours.

Variable Data Printing (VDP) adds tangible value to your services. In turn, it makes you irreplaceable to clients. It enables on-demand printing of QR codes. These codes are for order tracking or marketing. It also prints order numbers or personalized brand messages. This helps your clients boost engagement while growing your own business.

Optionally, anti-counterfeiting inks are available. These include UV-visible or temperature-sensitive types. They help brands prevent fake packaging and protect their reputation.

Built-in CCD visual inspection systems work in real time. They detect ink smudges, missing patterns, and color deviations. Furthermore, the system automatically rejects defective products. This ensures 99.9% batch consistency.

A leading food delivery packaging manufacturer adopted our printer. It’s a business just like yours. It serves top delivery platforms and chain restaurants. Soon after, the machine became their go-to for multi-material printing. It even helped them secure long-term, high-value contracts.

The printer handled various substrates. These included kraft paper burger boxes, pizza box, PP salad bowls, and PLA soup cups. It printed 6-color brand patterns at 40 m/min. Notably, it produced zero solvent emissions.

The printed packaging passed strict tests. These included food contact safety and 500-cycle friction tests. This impressed their clients and reduced rework. Most importantly, efficiency rose by 60%. Scrap rate also dropped by 75%. This directly improved profit margins—just as it can for you.

Custom QR code printing added extra value. It helped restaurants collect over 200,000 customer data points. Consequently, member conversion rates increased significantly.

This printer offers more than standard delivery packaging printing. It lets you expand your service portfolio easily. You can add catering tableware printing. You can also offer retail food packaging, like snack boxes or beverage sleeves. This opens new revenue streams with one investment.

Delivery packaging printing is part of our 1000 solutions challenge. It highlights the technology’s versatility. Looking ahead, future upgrades have clear focuses. They include compostable ink development. They also cover 3D texture printing for premium packaging.

For packaging manufacturers targeting food delivery printing, this printer is a high-ROI investment. It balances speed, safety, and customization. This helps you outcompete rivals and win more clients. It also lets you seize the $89.6 billion market opportunity. Ready to tailor a printing solution for your business? Leave a comment below with your specific needs. Our team will then connect with you to discuss a personalized plan.

Submit Request