News List

Traditional food decoration methods (stenciling, hand-piping) faced three critical limitations:

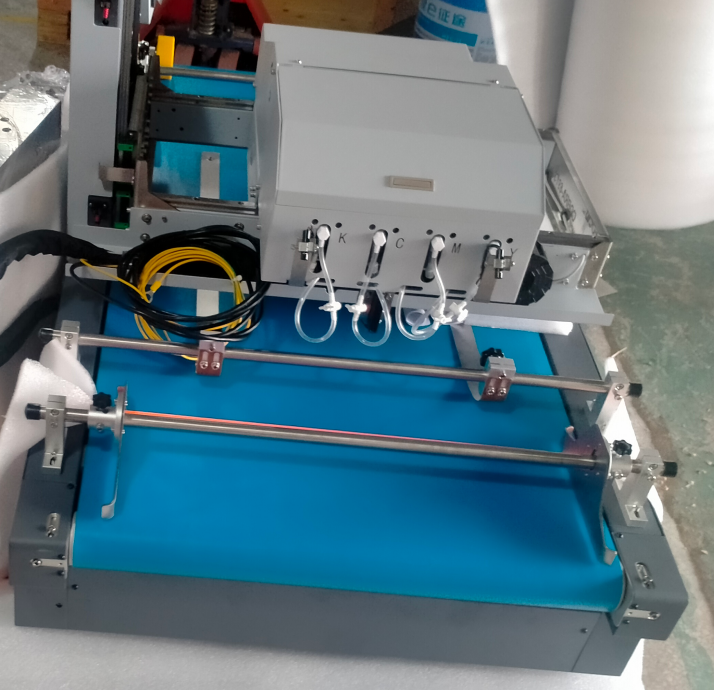

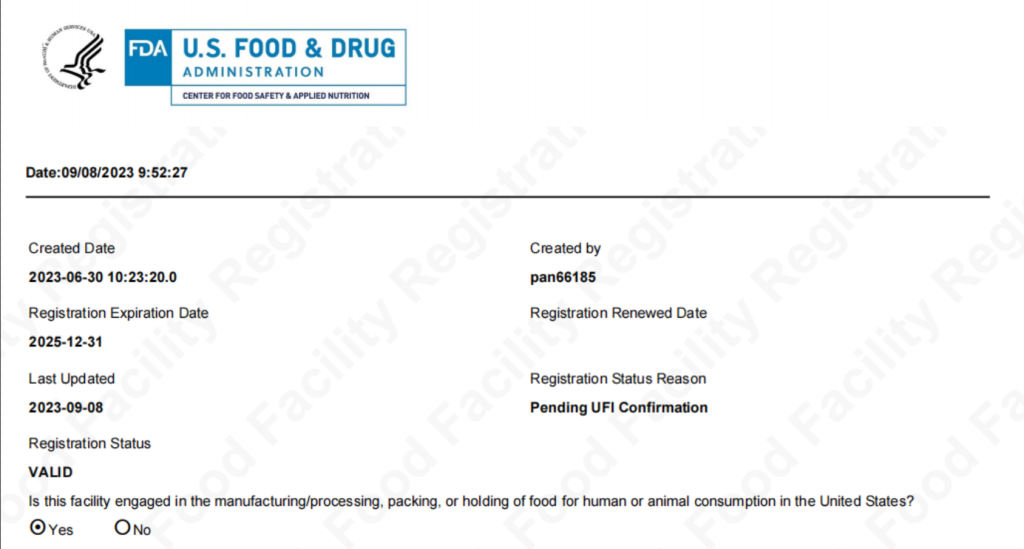

Phase Achievement Impact 2024.Q2 First bakery trial (macarons) 78% reduction in decoration time 2024.Q3 FDA GRAS ink certification Enabled US market entry 2024.Q3.

Case Study: SweetCelebration Cakes

After adopting FocusInc’s system:

✓ 15-minute personalized cake toppers (previously 2 hours)

✓ 34% increase in premium product sales

Client Success Stories with Single Pass Edible Ink Printing

Building on FocusInc's pioneering work in edible ink single pass printing applications, here are verified customer case studies demonstrating the real-world impact of this technology across various sectors. These examples showcase how businesses have leveraged single pass printers to enhance efficiency, customization, and safety.

Key Case Studies:

Café and Bakery Chain

A national chain implemented edible ink printers for custom cake and cookie decorations, while it cutts decoration time from 3 minutes to under 8 seconds per item. This innovation drove a 40% boost in customer engagement during holiday promotions, with FDA-compliant inks ensuring food safety.

Digital Cake Printing Studio

A boutique bakery specializing in personalized desserts used edible ink printing to produce intricate designs on cakes and macaroons at 1800+ units per hour. This reduced ingredient waste by 72% compared to manual methods.

For further technical specifications or regional implementations, consult the source materials directly.

Submit Request