News List

In the printing industry, UV printing holds distinct advantages over traditional printing methods. It delivers faster turnaround times and enhanced durability, making it a top choice for both businesses and individual users. Like all printing processes, however, UV printing comes with its own set of challenges, single pass UV printing common problems. This article explores the most common issues in single pass UV printing and provides practical solutions to resolve them.

Single pass UV printing is an advanced digital printing technology that leverages ultraviolet (UV) curing to create images on various substrates. Its core advantage lies in the print head only needing one pass over the substrate surface—unlike other printing methods that require multiple passes. This technology enables fast, efficient production of high-quality prints with exceptional color accuracy.

Ink adhesion ranks among the most critical challenges in single pass UV printing. It refers to the ability of ink to bond firmly to the substrate. Poor adhesion leads to ink smudging, fading, and peeling, ultimately resulting in low-quality prints. This issue frequently arises when printing on non-porous substrates such as plastics, metals, and glass.

Solutions: Proper substrate preparation is fundamental to improving ink adhesion. Thorough surface cleaning and targeted pre-treatment significantly boost ink bonding. Pre-treatment techniques including corona treatment, plasma treatment, and flame treatment drastically enhance adhesion on non-porous materials. Additionally, selecting ink tailored to the specific substrate is crucial. UV curable inks are formulated to bond with different substrates, effectively improving overall adhesion.

Banding affects the uniformity of printed images due to ink application inconsistencies. It manifests as uneven lines or streaks across prints, caused by irregular ink jetting or improper overprinting.

Solutions: Prevent banding by ensuring the print head remains unclogged and undamaged—clogs or damage cause inconsistent ink droplet sizes. Regular print head maintenance, such as cleaning and precise adjustment, effectively reduces banding issues. Adjusting print resolution settings also helps mitigate this problem. Opt for the slowest resolution setting acceptable for the job to guarantee consistent print quality.

Ink pooling is another prevalent issue in single pass UV printing. It occurs when ink accumulates in localized areas, creating thicker print sections, blotches, and other irregularities.

Solutions: Adjust ink density or print speed if ink pooling occurs. Choosing ink compatible with the substrate. Focusinc. R&D team will specifically formulate to test and match the professional material dyne value for the material in use—prevents pooling at the source. Regular print head maintenance and avoiding extreme humidity and temperature conditions further alleviate this problem.

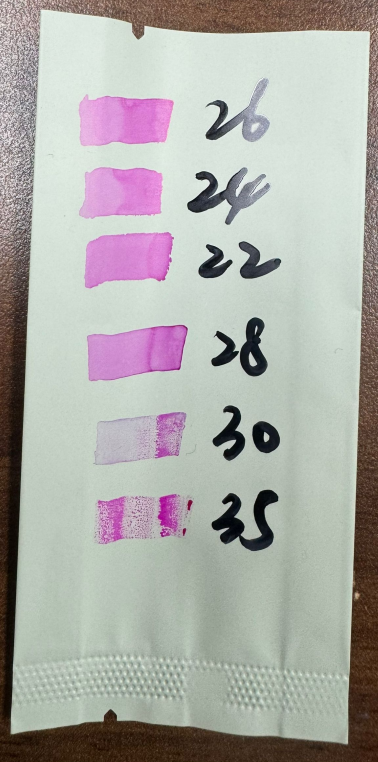

Gloss variation describes uneven reflectivity across the print surface, which gives printed images a patchy or mottled appearance. This issue typically occurs when printing on glossy or semi-glossy substrates.

Solutions: Use substrates designed specifically to maintain consistent gloss levels to address this issue directly. Calibrating the print head and fine-tuning printer settings also enhances overall print consistency, minimizing gloss irregularities.

Both under-curing and over-curing pose problems for single pass UV printing. Under-curing leads to ink adhesion failures, while over-curing causes substrates to become brittle or crack.

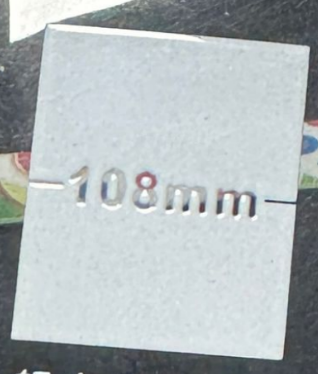

Solutions: FocusInc. Acalepha-891S series models uv single pass printer inkjet technology achieves proper curing by balancing UV lamp energy (measured in joules per square centimeter) and print speed. Avoid overexposure to UV light by lowering lamp energy or increasing print speed. Fix under-curing by raising lamp energy or reducing print speed, depending on the specific printing scenario.

Single pass UV printing outperforms traditional printing methods in multiple aspects. Yet, it still faces typical challenges including banding, ink adhesion, ink pooling, gloss variation, and curing issues. Addressing these problems effectively ensures successful single pass UV printing operations. Implementing the solutions outlined in this article will help you produce high-quality prints with greater reliability than ever before. Contact us to get more uv single pass printing system technology update !!! 🙂

Submit Request