News List

If your business prints labels, packaging, or textiles in bulk, you’ve probably asked: Is a high-speed continuous printer the right upgrade? Unlike traditional printers that require multiple passes to finish a design, continuous printers print an entire image in one go single pass way—slashing time, cutting errors, and scaling production. But how do you know if it’s right for your workflow?

Plus, we’ll break down whether a thermal or piezo model fits your needs best, including key details like printhead size and cost.

If your team spends hours (or days) churning out 1,000+ labels, cartons, or fabric rolls weekly, continuous printing will revolutionize your speed.

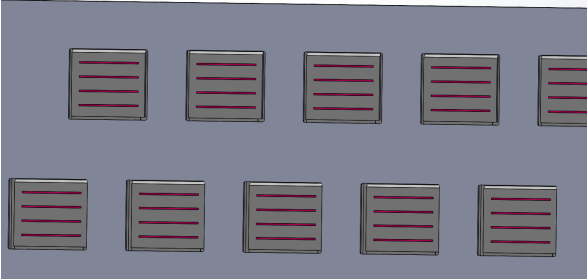

Traditional printers print in sections, requiring multiple passes over the same material. Continuous printers, (single pass printer) though, use a fixed printhead that spans the full width of your material. As the material moves through, the entire design is printed in one continuous run.

Example: A small packaging business printing 5,000 cereal box labels daily, with a traditional printer might take 8 hours. A continuous printer could cut that to 2–3 hours, freeing up time for other tasks.

Ever noticed slight color mismatches or alignment issues in bulk prints? These happen when traditional printers shift between passes—especially with flexible materials like fabric or thin plastic.

Continuous single pass printers eliminate this. Since the design is printed in one go, every piece looks identical—critical for branding (e.g., ensuring your logo color stays consistent across all product labels).

Who this affects: Food & beverage brands, clothing manufacturers, or any business where brand uniformity can’t be compromised.

If you’re expanding to thicker materials (cardboard, corrugated boxes), or flexible ones (textiles, vinyl), continuous single pass printers are built to handle it.

Their sturdy design and adjustable speed settings work with uneven or rigid surfaces, whereas traditional printers often jam or blur with these materials.

Example: A startup printing custom tote bags (coated fabric), and shipping boxes (cardboard) can use one continuous printer for both, instead of buying two separate machines.

Traditional printers need constant oversight: feeding material, adjusting settings, fixing jams. Continuous printers are more automated—load the material, set the design, and let it run.

This reduces the need for full-time staff to monitor the machine, cutting labor costs. For small businesses, this means reallocating team members to growth-focused tasks (like marketing or customer service).

As your business grows, demand for faster turnarounds and higher volumes will too. Continuous printers are scalable by design—they handle larger batches without slowing down or dropping quality.

If you’re planning to expand into new markets (e.g., adding private-label packaging for clients) or growing product lines, a continuous printer ensures you can meet demand without bottlenecks.

Once you’ve decided to upgrade, choosing between thermal and piezo printheads depends on your needs—including size, cost, and use case:

If you’re seeing 2+ of these signs, a high-speed continuous printer will save you time, reduce costs, and improve quality. Whether you need a budget-friendly thermal model for wide-format prints or a durable piezo printer for small, detailed jobs, we’ve got options tailored to your workflow.

Contact us today to discuss your printing needs—we’ll help you pick the right printer to grow with your business.

P.S. Ask about our demo—see how a continuous printer works with your materials before you buy!

Submit Request